| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : HTX

Model Number : HTX-P-01

Certification : POSI CERTIFICATE

Place of Origin : China

MOQ : 1Set

Price : 15000-80000/USD

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 50Sets/Month

Delivery Time : 30Days

Packaging Details : Carton

Product Name : Fence Panel machine

Feature : Automatic

Size : 7000*1000*1800mm

Capacity : 1200-1500m2

Power : 12.7 KW

Type : Artificial Stone product line

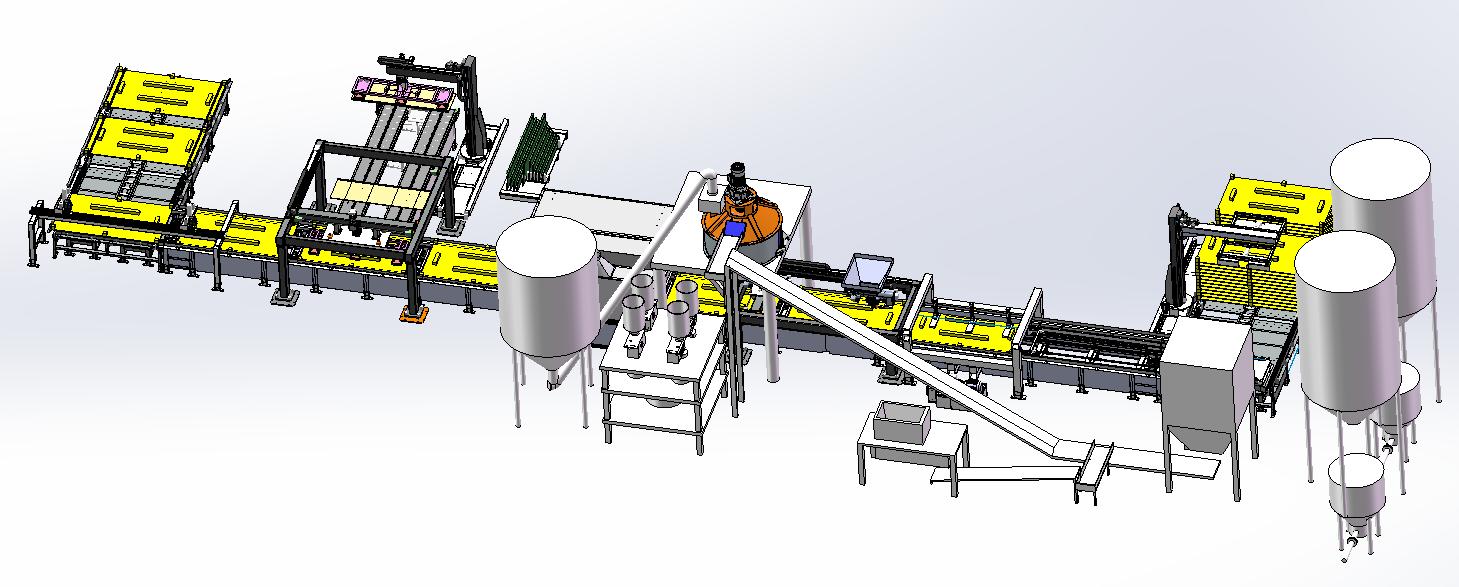

Sandstone retaining wall making machines are specialized machinery and equipment used to manufacture sandstone blocks or components for constructing retaining walls. Sandstone retaining walls are commonly used in landscaping and construction projects to create sturdy and visually appealing structures that retain soil and prevent erosion. The machines automate the process of producing sandstone blocks or components, ensuring efficiency, accuracy, and consistency in the manufacturing process.

Here are some key components and steps involved in a sandstone retaining wall making machine:

1.Raw Material Preparation: The process begins with the preparation of raw materials, which typically include sandstone aggregates, cement, water, and additives. The sandstone aggregates are obtained from quarries and processed to the desired size and quality. The raw materials are stored in separate containers or feeders and transported to the manufacturing area.

2.Mixing and Batching: The raw materials are precisely measured and mixed together in a batching plant or mixing machine. The mixing process ensures that the sandstone aggregates are uniformly combined with cement, water, and additives to create a well-blended mixture.

3.Molding or Casting: Once the sandstone mixture is prepared, it is transferred to the molding or casting machine. The machine shapes the mixture into the desired forms or components for the retaining wall. The molding process can involve techniques such as vibration, compression, or extrusion, depending on the specific design and requirements of the retaining wall blocks.

4.Finishing: Once the sandstone blocks or components have sufficiently cured, they may undergo finishing processes to achieve the desired surface texture or appearance. This can involve techniques such as sandblasting, brushing, or other surface treatments to enhance the natural look of the sandstone.

5.Quality Control and Packaging: The finished sandstone blocks or components are inspected for quality, including dimensions, strength, color consistency, surface finish, and other desired properties. Any defective units are discarded, and the approved ones are packaged and stored in a designated area. They are then ready for transportation to construction sites or distribution to customers.

Specification:

| Name | Model | Specification | Size(mm) | Power(Kw) | Capacity(m2/day) | Weight(Kg) |

| Wet Cast Machinery | HTX-P-01 | Hydraulic driving;Auto feeding; vibrating and timing feeding | 7000*1000*1800 | 12.7 | 1000-1500 | 2000 |

| Wet Cast Machinery | HTX-P-02 | Chain drived;Auto feeding,auto vibration | 8000*1100*1600 | 4.05 | 800-1000 | 1500 |

Applications

Wet cast machinery, is suitable for different silicone molds, rubber molds and plastic molds, size range from 200*200mm to 1500*1500mm, available for producing the artificial stone both for paving tile molds, 3D wall molds, wall panel molds, roadside stone molds, retaining wall molds, wall cap molds, etc.

Support and Services

Wet Cast Machinery technical support and services include:

|

|

Full-Automatic Sandstone Retaining Wall Making Machine Artificial Stone Manufacturing Machine Images |