| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : HTX

Model Number : HTX-P-01

Certification : POSI CERTIFICATE

Place of Origin : China

MOQ : 1Set

Price : 40000-200000/USD

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 50Sets/Month

Delivery Time : 30Days

Packaging Details : Carton

Product Name : Curbstone Machine

Voltage : 220V

Size : 1500*1300*2500cm

Key Selling Points : High Productivity

Feature : Automatic

Capacity : 1200-1500m2

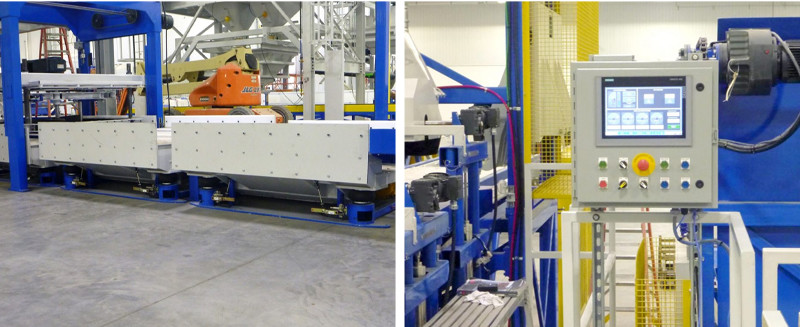

Fully Automatic Concrete Wall Fence Panels Making Machine Curbstone Machine

curbstone machine, also known as a curb making machine or curb forming machine, is a specialized piece of equipment used for the automated production of concrete curbstones or kerbstones. These machines are designed to streamline and optimize the manufacturing process, allowing for efficient and consistent production of curbstones with various shapes, sizes, and designs.

Here's a general overview of how a curbstone machine works:

Concrete Batching Plant: The curbstone machine is typically connected to a concrete batching plant or mixer. The batching plant accurately measures and combines cement, aggregates (such as sand and gravel), water, and additives to create the concrete mixture. The quality and consistency of the concrete mix are crucial for producing durable and high-quality curbstones.

Mold Preparation: The machine is equipped with molds or formwork that define the shape and dimensions of the curbstone. These molds can be customized to produce different curbstone profiles, including straight curbs, radius curbs, and interlocking curbs.

Concrete Feeding: The concrete mixture from the batching plant is fed into the curbstone machine. The machine may have a conveyor system or other mechanisms to transport the concrete to the mold or formwork.

Vibration and Compaction: Once the concrete is in the mold, the curbstone machine applies vibrations and compaction to ensure proper consolidation. Vibrations help remove air bubbles and settle the concrete evenly throughout the mold, resulting in curbstones with improved strength and durability.

Curing: After compaction, the molds with the freshly poured curbstones are usually moved to a curing area. Curing is a critical step that allows the concrete to gain strength and develop its desired properties. The curbstones may be covered or subjected to temperature and humidity control to optimize the curing conditions.

Demolding and Finishing: Once the curbstones have sufficiently cured and hardened, the molds are opened, and the finished products are demolded. The curbstones may undergo additional processes, such as surface finishing or edge profiling, to achieve the desired appearance and functionality.

Quality Control and Packaging: Throughout the production process, quality control measures are implemented to ensure that the curbstones meet the required standards. This may involve inspecting dimensions, surface quality, and strength properties. After quality control checks, the curbstones can be packaged and prepared for storage or transportation.

Curbstone machines can be fully automatic or semi-automatic, depending on the level of automation and the specific features of the machine. They are designed to minimize manual labor, increase productivity, and ensure consistent quality in curbstones production. These machines are widely used in road construction, landscaping, and urban development projects.

Specification:

| Name | Model | Specification | Size(mm) | Power(Kw) | Capacity(m2/day) | Weight(Kg) |

| Wet Cast Machinery | HTX-P-01 | Hydraulic driving;Auto feeding; vibrating and timing feeding | 7000*1000*1800 | 12.7 | 1000-1500 | 2000 |

| Wet Cast Machinery | HTX-P-02 | Chain drived;Auto feeding,auto vibration | 8000*1100*1600 | 4.05 | 800-1000 | 1500 |

Applications

Wet cast machinery, is suitable for different silicone molds, rubber molds and plastic molds, size range from 200*200mm to 1500*1500mm, available for producing the artificial stone both for paving tile molds, 3D wall molds, wall panel molds, roadside stone molds, retaining wall molds, wall cap molds, etc.

Support and Services

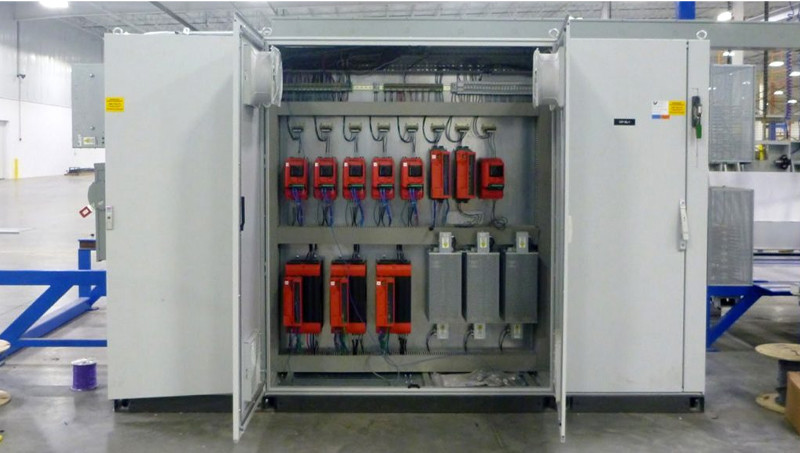

Wet Cast Machinery technical support and services include:

|

|

Fully Automatic Concrete Wall Fence Panels Making Machine Curbstone Machine Images |